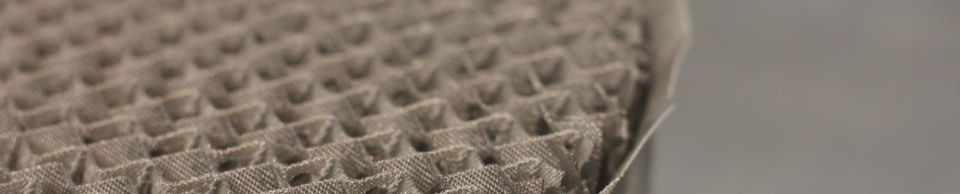

HETP, Inc. Structured Wire Gauze Packing is comprised of proprietary designed wire mesh corrugated sheets. These allow thin liquid films to be continuously spread across the tower as liquid flows through the packing. Capillary action and high surface areas result in maximum exposure between liquid and vapor phase, which equates to high mass transfer efficiency, especially at low liquid rates.

Ideal for processing specialty chemicals, isomers, pharmaceuticals, flavors, fragrances and other temperature sensitive materials, the very high efficiency and low pressure drop of this packing are unequaled.

Key Benefits:

- High number of theoretical stages per foot

- Low pressure drop per theoretical stage

- Low hold-up

- Self wetting surface

Applications:

- Low liquid-loading systems

- For a large number of theoretical stages

- Vacuum from 1 mbar to atmospheric

- Raising performance of an existing column

- For smaller overall column height

- Batch and continuous columns

Other:

- Materials: All stainless steels, nickel, hastelloy, Inconel, monel and many others.

- Installed diameters from 2” to 15’ -6”

- Custom height layers 2” – 6.75”

HETP, Inc. • 1600 Old Angleton Road • Clute, Texas 77531

Ph: 979-265-0949 • Fax: 979-265-7856

Contact: info@hetpinc.com